Difference between revisions of "F17: Alpha"

Proj user1 (talk | contribs) (→Hardware Design) |

Proj user1 (talk | contribs) (→Hardware Design) |

||

| Line 375: | Line 375: | ||

The Geographical controller makes use of the following two modules: | The Geographical controller makes use of the following two modules: | ||

| − | GPS | + | '''GPS''' |

Revision as of 05:52, 13 December 2017

Contents

Project Title

Alpha - Self-navigating RC car using CAN communication based on FreeRTOS.

Git Link - ALPHA

Git Users:

- Anirudh1313

- chhavi17

- DoyalPatel

- jigar29

- kthnptl

- rajvisharia

- ShubhamKulkarni93

- SnehaSharma

- SushmaSJSU

- SuchetaCiyer

Abstract

This section should be a couple lines to describe what your project does.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

- Master Controller

- Jigar Agarwal

- Sucheta Iyer

- Motor Controller

- Geographical Controller

- Krishna Sai Anirudh Katamreddy

- Chhavi Mehta

- Sensor Controller

- Sneha Sharma

- Sushma Macha

- Communication Bridge Controller + LCD

- Kathan Patel

- Android Application

- Doyal Patel

- Sneha Sharma

- Testing

- Doyal Patel

- Jigar Agarwal

- Sucheta Iyer

Schedule

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 09/15/2017 | 09/16/2017 |

|

Completed |

| 2 | 09/17/2017 | 10/03/2017 |

|

Completed |

| 3 | 10/04/2017 | 10/10/2017 |

|

Completed |

| 4 | 10/11/2017 | 10/17/2017 |

|

Completed |

| 5 | 10/18/2017 | 10/24/2017 |

|

Completed |

| 6 | 10/25/2017 | 10/31/2017 |

|

Completed |

| 7 | 11/01/2017 | 11/07/2017 |

|

Completed |

| 8 | 11/08/2017 | 11/14/2017 |

|

Completed |

| 9 | 11/15/2017 | 11/21/2017 |

|

Completed |

| 10 | 11/22/2017 | 11/29/2017 |

|

In Progress |

| 11 | 11/30/2017 | 12/14/2017 |

|

In Progress |

| **************Final Demonstration.*************** | To Do |

Parts List & Cost

| Item# | Part Desciption | Vendor | Datasheet | Qty | Cost |

|---|---|---|---|---|---|

| 1 | RC Car | 1 | |||

| 2 | CAN Transceivers MCP2551-I/P | Microchip [1] | MCP2551-I/P Datasheet | 8 | Free Samples |

| 3 | Sonar Sensor | Amazon [2] | Maxbotix EZ1 MB 1010 Datasheet | 4 | $24.95 |

| 4 | Headlights | ||||

| 5 | NiMH Battery | From seniors | 2 | ||

| 6 | Charger for NiMH/NiCd Battery | From seniors | 1 | ||

| 7 | Character LCD Display |

Sensor Module

The sensor module refers to the sensors and the embedded board that controls the sensors. In this project we have used four Maxbotix EZ0 ultrasonic sensors. Each of these is mounted in four positions. Three sensors face the front of the car and are positioned in the centre, the left edge and right edge of the car. One sensor is mounted on the back of the car.

The main goal of the sensor module is to detect the distance to an obstacle, from the car and provide this information to the driver module so that it can successfully avoid the obstacle.

Hardware Design

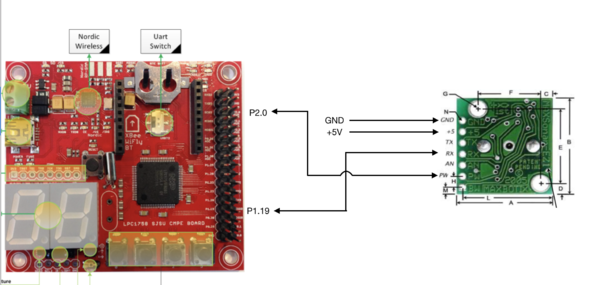

The sensors used are LV-MaxSonar-EZ1 Ultrasonic Range Finder MB1010.

The valid sensors output is a value between 6 and 254. This value is in inches and represents the distance to the obstacle, from the sensor. It is to be noted that if the obstacle is closer than 6 inches from the sensor it will not be detected.

The sensor provides output in three forms; As a pulse on the PW pin, where pulse width represents the distance to obstacle; As an analog voltage on the AN pin; As a digital output on the TX pin, in RS-232 format. We have used the PW pin in this project to receive the input from the sensor.

It is to be noted that if two sensors which are placed so that their beams/detection areas overlap, are ranging at the same time, they cause each other interference and hence incorrect values. Hence we trigger each sensor separately one by one so that at any time, only one sensor is ranging.

<insert image of sensor here. mark all the pins - vcc gnd tx rx pw> <insert image of two sensors placed close by so that their beams are overlapping>

Hardware Interface

Pin connections for each sensor is as follows:

PW (Pin 2) - GPIO Pin configured as interrupt to receive input from sensor

RX (Pin 4) - GPIO Pin configured as output to trigger the sensor

VCC (Pin 6) - +5V

GND (Pin 7) - GND

Pin connections for the middle sensor are displayed.

Software Design

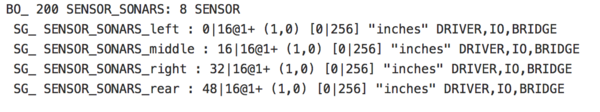

As described in the previous section, the sensors are triggered one by one to prevent corruption of data. In our implementation the sensors are triggered in the following order: middle, right, left and back. The back and left sensors are triggered together since they would not interfere with each other.

Every sensor needs a power up time of 250 ms and some time to calibrate and take the first reading. After this period the sensor can provide a reading every 49 ms. In our implementation, all 4 sensor values are taken every 120 ms and put on the CAN bus. The format of the CAN message is shown in the following snippet taken from the DBC file. It can be observed that the sensor message has a high priority since it is critical to the operation of the car.

Implementation

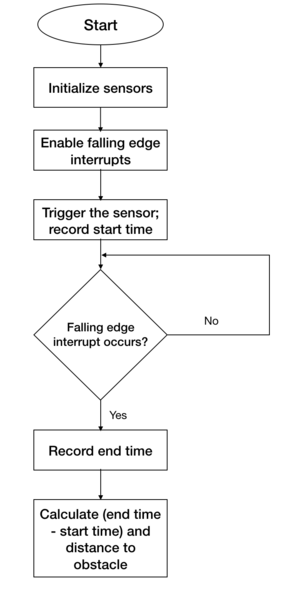

The following steps are followed to get a valid sensor reading.

1. Initialize the sensors - account for power up and calibration delay.

2. Enable falling edge interrupts and setup callback functions - this is to record the pulse width output of the sensor

3. Trigger each sensor and record the current time. This is the start time.

4. When falling edge interrupt occurs record the time. This is the end time.

5. Calculate pulse width using the start and end time. This pulse width would indicate the distance to the obstacle.

Testing & Technical Challenges

There were a few difficulties during implementation and testing of the sensors. Lessons learned include the following:

1. Research different types of sensors, find out the strengths and weaknesses of each before making a decision.

2. Ultrasonic sensors need to be slightly tilted upwards when mounted on the car to prevent them from accidentally detecting ground as an obstacle. This becomes especially necessary when testing on a slope/ramp.

3. Ultrasonic sensors are very sensitive and care needs to be taken while soldering them. Accidental overheating can cause them to be destroyed.

4. The ultrasonic sensors provide more range when +5V is used as supply rather than +3.3V.

5. Testing both indoors and outdoors is necessary to check if the sensor readings are accurate in both conditions.

Motor Module

Motor module is one of the five controllers used in our self-driving car. Motor controller is responsible for driving the car forward and for steering the vehicle. The motor module has two motors viz.DC motor and Servo motor. DC motor makes the car move forward and reverse. Servo motor steers the car either left or right. Along with the two motors we have the rpm speed sensor which is interfaced with our controller to control the speed of DC and move the car at a desired speed in Miles per Hour(MPH).

Team Members

Hardware Design

Hardware Interface

Software Design

Implementation

The following steps

1.

2.

Testing & Technical Challenges

There were a few difficulties during implementation and testing of motors

1.

2.

Geographical Controller

The geographical Controller is responsible for navigating the car in the direction of the destination selected by an android user. It uses a compass module for getting the heading angle with respect to the North and a GPS module which returns the current location of the car. After a particular destination has been chosen from the android app, the bridge module generates a number of checkpoints according to the shortest path algorithm. These are then sent to the geographical controller one by one. Using each of them, the bearing angle and the distance between the car and the checkpoint is calculated. Subsequently, the angle that the car should turn is determined and sent to the master module. On reaching the destination, the car is stopped.

Hardware Design

The Geographical controller makes use of the following two modules:

GPS

COMPASS

CMPS11 tilt-compensated compass module is employed for getting a heading angle value between 0-359. It requires a power supply of 3.6-5V. It can be interfaced via both serial(UART) and I2C. We have incorporated the I2C interface in which the 'mode' pin of the compass is left unconnected. It has a 28-byte array of registers and compass bearing can be read from 8-bit register 1.

Calibration of CMPS11 - We are using switch 1 and switch 2 of the SJOne board for entering and exiting the calibration mode respectively. When switch 1 is pressed, a 3-byte sequence of 0xF0, 0xF5 and 0xF6 is sent to the command register 0 and an led on the module starts blinking indicating the calibration mode. Compass is then slowly rotated in all 3 dimensions to get both negative and positive maximums. Only after the led completely extinguishes, switch 2 is pressed and 0xF8 command is sent to exit the calibration mode. More accurate readings can be achieved by performing calibration meticulously.

Hardware Interface

GPS

COMPASS

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

<Bug/issue name>

Discuss the issue and resolution.

Android Application

An google map based android application is developed to provide information to Alpha which is required to reach destination like routing information between source and destination as well as software based commands to start and to stop Alpha. This application also displays information about current position and heading angle of Alpha.

Hardware Design

N/A

Hardware Interface

Interfaced to Bluetooth module (As explained in Bluetooth Module).

Software Design

1. Bluetooth: Bluetooth allows wirelessly exchange data with another Bluetooth device. Here, We are using Bluetooth to communicate between our self-driving car and mobile application.

- 1.1. Enable Bluetooth : Bluetooth of mobile phone programmatically enabled using BluetoothAdapter. If Bluetooth of mobile is not enabled than enable it.

- 1.2. Connect to Bluetooth on Alpha : A new Socket created using UUID of Bluetooth device on Alpha. Connection request sent by calling connect method on created socket. Here, Connect is blocking call which will return if connection request is accepted and connection established or exception thrown. To establish automatic connection between alpha and mobile device a separate thread is created which continuously check the connection and try make connection in case Alpha is not connected. A connection indicator is used to show connection status.

- 1.3. Read from Alpha : Read the data from input-stream and convert it in accurate Latitude, Longitude and Heading angle. A separate thread is used to continuously read data and update it on the screen.

- 1.4. Write to Alpha : Write the data on output stream so that it can be available on Alpha. In this application Start bit, Stop bit and routing check points are sent to move alpha.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.